Metamaterials refer to unique materials with negative indices of specific physical properties such as Poisson’s ratio (PR), coefficient of thermal expansion (CTE), and compressibility. Due to their counterintuitive deformation characteristics, metamaterials have great potential in improving mechanical, thermal and other properties. The advantages. For example, negative Poisson’s ratio (NPR) metamaterials undergo transverse expansion rather than contraction deformation under longitudinal stretching, thereby improving the shear stiffness, indentation resistance, fracture toughness, etc. of the structure. Compared with metamaterials that only exhibit a single negative property, metamaterials with both NPR and controllable CTE provide more options for multiphysics. Such metamaterials have potential applications in mechanical and thermal field devices, such as solar panels in deployable space structures and gapless tracks for high-speed trains. Many works have reported this type of metamaterials from the aspects of topological design, deformation mechanism and theoretical modeling. However, current research only gives the special configuration of metamaterials, and the basic rules for designing metamaterials including NPR and controllable CTE have not been reported.

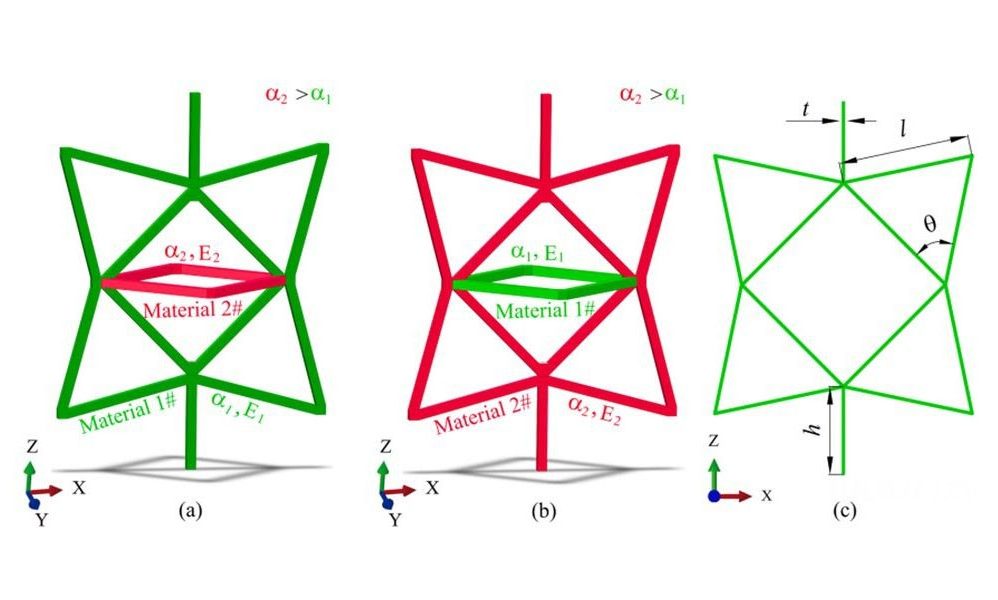

Wang Zhonggang’s team at Central South University established a set of basic design rules for metamaterials based on Mohr’s theorem, and proposed a new star-shaped metamaterial composed of two materials as shown in Figure 1, which has both negative Poisson’s ratio and negative thermal expansion characteristics. Taking Figure 1(a) as an example, as the temperature increases, the metamaterial unit cell undergoes thermal contraction in the x and z directions due to the incompatibility of the thermal deformation of the material. At the same time, under the mixed effects of re-entry and compression-expansion mechanisms, the unit cell exhibits NPR in three main directions.

In addition, the author applied the method of superstatically indeterminate structures to predict the deformation of the unit cell in different directions, and used Mohr’s theorem to calculate the bending moment, axial force and shear force on each pillar in the unit cell, thus establishing a prediction superstructure. Theoretical models of structural unit cell properties. The accuracy of the theoretical model was verified using numerical simulation methods. The results are shown in Figure 2. The CTE and elastic properties of the numerical simulation are in good agreement with the calculation results of the theoretical model.

Based on the proposed basic rules for metamaterial design, the author established a theoretical mechanical model and thermodynamic model of a new metamaterial that combines NPR and NTE, and the finite element analysis results are in good agreement. The described metamaterial shows broad tunability in CTE and PR, with great potential in thermal and mechanical applications such as thermal actuators requiring NTE, deployable spatial structures, sensors, and dental fillings. wait.