In January 2024, researchers from the University of Colorado Boulder developed a new process for determining material properties in inkjet additive manufacturing. The findings, dubbed “pantone for properties” by researchers Robert MacCurdy and Lawrence Smith, outline how multi-material inkjet 3D printing can create specific material properties by combining different resin materials. The research content has been published in the journal “Advanced Materials”, titled “Digital Multiphase Composites via Additive Manufacturing”

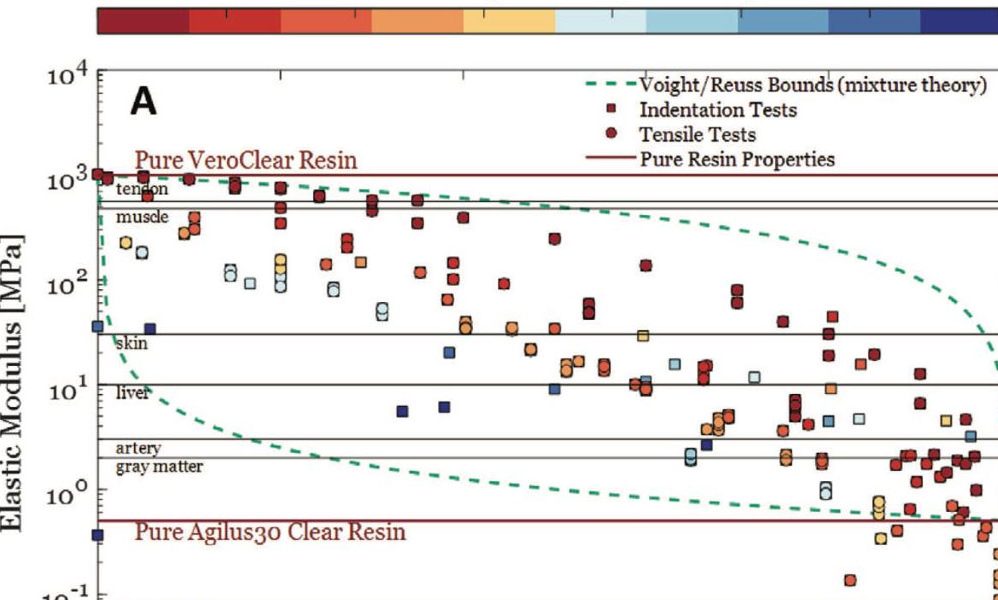

Similar to mixing different primary colors to create specific colors, the researchers illustrate how repeatable 3D printing material properties can be achieved by mixing three “primary” materials. These materials include soft elastomers, hard plastics and liquid components. In the study, the researchers used custom software to design hundreds of digital composite samples. After 3D printing, the mechanical properties of the samples were tested and characterized. Analytical plots are then created that compare the composition and mechanical properties of the composite materials, enabling “inverse materials design.”

This process reverses the traditional material selection process. Typically, engineers look for a suitable material with the desired material properties and then design based on that material. Instead, the new approach can first specify a set of desired material properties for a part and then 3D print it. The authors say this study is the first to characterize a digital material composite made from three inkjet materials with different mechanical properties. Previous studies have only evaluated composites of two materials, which “failed to achieve mechanical realism.”

The potential applications of this process are diverse. The researchers highlight 3D printing of mechanically sound synthetic biological tissues as a potential use case. Using inverse materials design methods, users can design and 3D print materials with any combination of stiffness and toughness needed to accurately mimic biological tissue.

“Pantone color card” of 3D printing material properties

Multi-material inkjet 3D printers eject droplets of photopolymer resin that are then cured by a UV light source to form 3D objects. 3D printer manufacturer Stratasys’ Agilus and Vero inkjet 3D printing resins have different properties after curing. Agilus becomes a tough and flexible elastomer material, while Vero forms a rigid plastic. The two materials can be combined in different proportions to form composites with different properties. However, the performance possibilities of these combinations are limited.

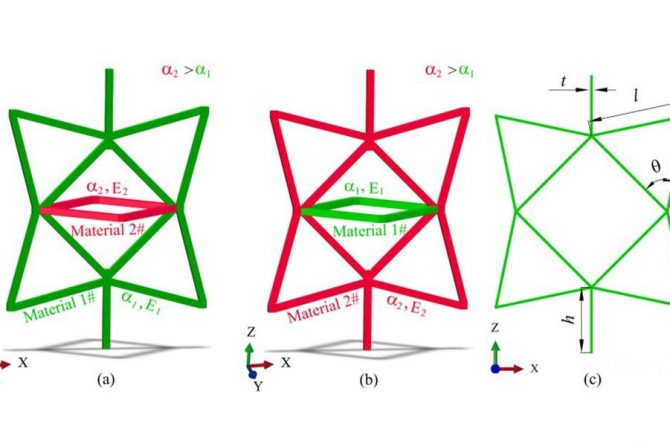

To achieve greater freedom in material properties, University of Colorado researchers added a third liquid material to the composite design process. During the study, 188 tests were conducted on 110 unique composite formulations. Through experimental observation and verification using 3D printed parts, the researchers showed that by combining 3 substrates, mechanical properties such as elasticity and toughness can be independently determined.

The researchers used stamping testing for mechanical testing. The team recorded the indentation distance and force of the 3D printed sample, and the test was terminated when the material failed.

The test results highlight that the elastic modulus and toughness properties are decoupled and can be specified independently during the 3D printing process. What’s more, the study concluded that any two material properties can be decoupled using this approach. This is achieved by adding a third liquid-based material to the composite design process. The researchers also demonstrated the inverse design of 3D-printed objects with prescribed properties, by creating a mapping between composite composition and macroscopic material properties at the microscale.

Using analytical models and mathematical equations, the researchers successfully used these mappings to accurately estimate the mechanical properties of a variety of inkjet composites combining elastomers, rigid and liquid resins. Ultimately, the researchers believe the findings have huge potential for medical applications.

Using current methods, researchers have struggled to obtain accurate material properties that reflect biological tissue. The results of the study are said to enable the material’s stiffness and toughness to be changed simultaneously and independently, allowing researchers, designers and medical practitioners to 3D print realistic and mechanically convincing synthetic biological tissues.

Inkjet 3D printing research

MacCurdy and Lawrence’s study is not the first to explore the potential of multi-material inkjet 3D printing for medical applications. Researchers from the MIT Media Lab, Harvard University’s Wyss Institute, and Dana-Farber Cancer Institute have developed a method to 3D print hybrid living materials. Called the Hybrid Active Materials (HLM) manufacturing platform, the team uses multi-material inkjet 3D printing and custom material formulations to combine resins and chemical signals. These signals activate responses in bioengineered microorganisms, offering the potential for medical devices with therapeutic agents.

In this study, researchers combined suitable support resins with structural resin materials to create 3D printed parts that are absorbent and retain chemical signals to control the behavior of living organisms. The HLM platform can utilize three to seven different resins with different properties, mixed in proportions with synthetic biomaterials.

A team at Martin Luther University Halle-Wittenberg has developed a hybrid additive manufacturing process that combines extrusion and inkjet 3D printing. This approach enables the direct integration of liquid ink into a solid material matrix. One of its key applications is the integration of active medical ingredients into 3D printed drug delivery devices during the initial manufacturing stage.