Oerlikon has more than 80 years of experience in materials development and production. Relying on the professional technology of American powder factories and German additive manufacturing bases, we can provide customers with metal materials such as titanium alloys, nickel-based alloys, cobalt-chromium alloys, stainless steel, mold steel, and customized high-end parts additive manufacturing solutions. Currently, Oerlikon’s products and services are widely used in aerospace, energy, medical and automotive fields.

block Oerlikon’s additive manufacturing capabilities

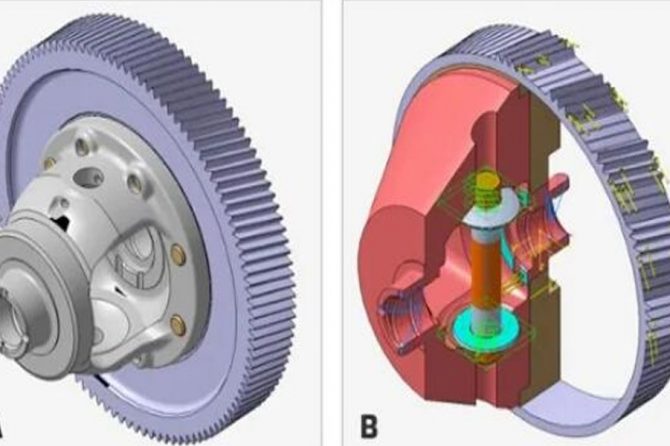

It has a variety of metal additive manufacturing equipment and a research center dedicated to printing testing and process parameter optimization.

Can perform physical and chemical analysis

Global sales and logistics network

NADCAP certified production facility

Flexible warehousing policy

Locally stocked powder can arrive at the client within 2 days at the fastest

Customized reusable packaging and labels

Materials are traceable

Long-term supply agreements available

block Oerlikon Additive Manufacturing’s existing powder grades

Block additive manufacturing powder properties

Developed specifically for industrial applications

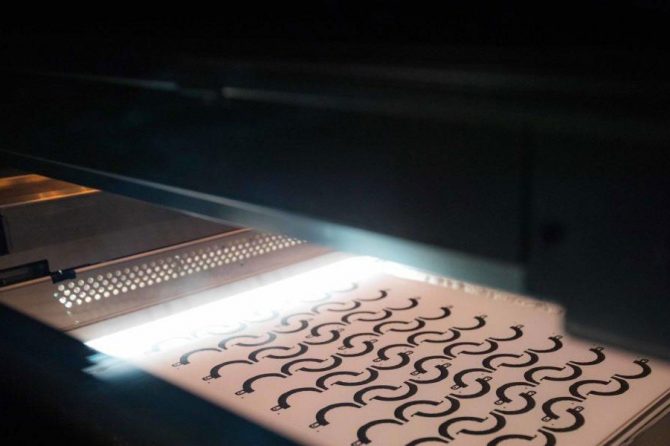

High purity spherical metal powder with excellent high tap density and excellent flowability

Powder particle size distribution tailored for additive manufacturing processes

Offers the advantages of high reliability and repeatability

block powder applicable process

Laser Powder Bed Melting (PBF-LB)

Electron beam powder bed melting for Ti-6Al-4V (PBF-EB/Ti6Al4V)

energy deposition (DED)

4 metal powders recommended by block

I High temperature alloy nickel base 738

MetcoAdd™ 738A is a nickel-based high-temperature alloy. Through optimization, printing cracking can be effectively reduced and printability improved. This powder can print crack-free products.

Application areas:

Aerospace: turbine engine hot-end components, blades and heat shields

I High temperature alloy nickel base 230

MetcoAdd™ H230-A is a nickel-based powder product whose chemical composition is close to the American aviation standard AMS5891 bar standard (close to the national standard GH3230). The room temperature static properties of the printed test bar after heat treatment are at the same level as AMS5891, and it has excellent high-temperature tensile and creep properties.

Application areas:

Aerospace: engine components

Energy generation: gas turbine components

General Industry: High Temperature Resistant Components

I High temperature alloy cobalt base 188

MetcoAdd™ H188-A is a cobalt-based powder product whose chemical composition is close to the American aviation standard AMS5608 plate standard (close to the national standard GH5188). The room temperature static performance of the printed test rod after heat treatment is at the same level as AMS5608.

Application areas:

Aerospace engines and gas turbines: transition tubes, combustion chambers, injection pipes, flame stabilizers, linings

I High temperature alloy cobalt based 509

MetcoAdd™ MM509-A is a Co-Ni-Cr-W-Ta series alloy with a chemical composition close to Mar-M-509. The room temperature static performance of the printed test rod after heat treatment is at the same level as that of the cast Mar-M-509.

Application areas:

Aerospace engines and gas turbines: guide blades, vane rings